-

High Voltage Ceramic Capacitor

-

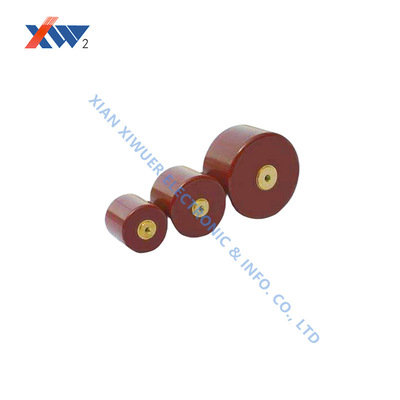

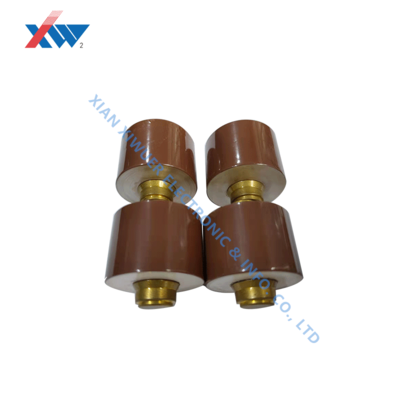

High Voltage Doorknob Capacitors

-

High Voltage Film Capacitor

-

Live Line Capacitors

-

Surge Protective Device

-

High Voltage Vacuum Circuit Breaker

-

Switchgear Temperature Sensor

-

Voltage Instrument Transformers

-

Capacitive Voltage Detector

-

Capacitive Voltage Divider

-

Capacitive Insulator

-

MOV Metal Oxide Varistor

-

PTC NTC Thermistor

-

High Voltage Resistors

-

Richard“XIWUER is very innovative. They have provided excellent, intuitive service, looking ahead into the future as to what we might need.”

Richard“XIWUER is very innovative. They have provided excellent, intuitive service, looking ahead into the future as to what we might need.” -

Mike"XIWUER's dedication to designing different specifications to meet our stringent processing requirements is a testament to our years of research and development."

Mike"XIWUER's dedication to designing different specifications to meet our stringent processing requirements is a testament to our years of research and development." -

Marry"XIWUER has impressive research capabilities and demonstrates good prototyping capabilities and high product quality."

Marry"XIWUER has impressive research capabilities and demonstrates good prototyping capabilities and high product quality."

High Voltage Ceramic Doorknob Capacitor with Partial Discharge <5PC at 20kV, Temperature Coefficient -4700 ±1000 ppm/°C, and Storage Temperature -25°C to +85°C

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Diameter | 90 | Dissipation Factorrange | 0.5% Maximum |

|---|---|---|---|

| Temperature Coefficien | -4700 ±1000 Ppm/°C | Partial Discharge | Less Than 5PC At 20kv |

| Working Voltage | 60kVDC | Part No | CT8-1 |

| Dissipation | ≦0.0040 | Applications | High Voltage Power Supplies, RF Amplifiers, Pulse Generators |

| Rated Voltage | 10kV - 100kV | Termination Style | Solder Lug |

| Capacitance | 1100pF | Capacity Accuracy | ±10% |

| Storage Temperature | -25°C To +85°C | Rate Voltage | 50KV |

| Threaded Terminals | M4x0.7 | ||

| Highlight | Partial Discharge <5PC High Voltage Ceramic Capacitor,Temperature Coefficient -4700 Doorknob Capacitor,Storage Temperature -25°C HV Ceramic Capacitor |

||

The "ventricle" responsible for energy storage and precise release in high-performance electrical systems.

Building high-performance Pulse-Shaping Networks (PFNs) presents significant challenges that our specialized capacitors overcome:

| Challenges | Limitations of Conventional Capacitors | Our Solutions |

|---|---|---|

| Extreme Voltages | Prone to Dielectric Breakdown, Leading to System Failures | Ultra-High Dielectric Strength: Utilizing specialized ceramic materials and a vacuum epoxy potting process, these capacitors withstand tens of kilovolts of high voltage, doubling reliability. |

| High Instantaneous Currents | Severe internal heating and excessive inductance leading to pulse distortion | Extremely Low ESL/ESR: A unique low-inductance structural design and metallized electrodes ensure nanosecond response and withstand surge currents in the hundreds of kiloamperes. |

| Synchronous Consistency | Capacitance drift and dispersion are significant, leading to pulse waveform collapse | Excellent Consistency: Strict process control and 100% burn-in testing ensure minimal capacitance deviation across the capacitor bank, enabling perfectly synchronized discharge. |

| Long-Term Reliability | Short lifespan under frequent charge and discharge cycles, resulting in high maintenance costs | Extremely Long Cycle Life: Optimized material systems enable performance degradation of less than 2% through >1,000,000 extreme charge and discharge cycles. |