-

High Voltage Ceramic Capacitor

-

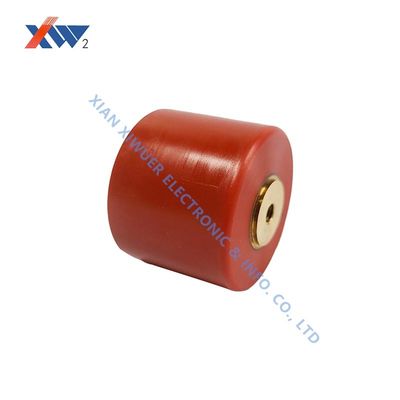

High Voltage Doorknob Capacitors

-

High Voltage Film Capacitor

-

Live Line Capacitors

-

Surge Protective Device

-

High Voltage Vacuum Circuit Breaker

-

Switchgear Temperature Sensor

-

Voltage Instrument Transformers

-

Capacitive Voltage Detector

-

Capacitive Voltage Divider

-

Capacitive Insulator

-

MOV Metal Oxide Varistor

-

PTC NTC Thermistor

-

High Voltage Resistors

-

Richard“XIWUER is very innovative. They have provided excellent, intuitive service, looking ahead into the future as to what we might need.”

Richard“XIWUER is very innovative. They have provided excellent, intuitive service, looking ahead into the future as to what we might need.” -

Mike"XIWUER's dedication to designing different specifications to meet our stringent processing requirements is a testament to our years of research and development."

Mike"XIWUER's dedication to designing different specifications to meet our stringent processing requirements is a testament to our years of research and development." -

Marry"XIWUER has impressive research capabilities and demonstrates good prototyping capabilities and high product quality."

Marry"XIWUER has impressive research capabilities and demonstrates good prototyping capabilities and high product quality."

Precise Injection And Stable Circulation: The Key Role Of High-voltage Doorknob Capacitors In The Pulsed Magnet Power Supply Of Synchrotron Radiation Light Sources

| Place of Origin | XIAN, CHINA |

|---|---|

| Brand Name | XIWUER |

| Certification | ISO9001,ISO14001,ISO45001 |

| Document | High Voltage Ceramic Capaci...25.pdf |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | Carton |

| Delivery Time | 5-7days |

| Payment Terms | L/C,T/T |

| Supply Ability | 4,000,000 pcs a year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Dissipation | ≦0.0040 | Withstanding Voltage | 1.5Ur● 1min |

|---|---|---|---|

| Insulation Resistance | ≧1.0×105MΩ | ||

| Highlight | high voltage doorknob capacitors pulsed magnet,synchrotron radiation capacitors stable circulation,high voltage capacitors with warranty |

||

High-voltage doorknob capacitors in the pulsed magnet power supply of synchrotron radiation light sources

Drawing:![]()

Parameters:

| No. | Specification | Dissipation | Withstanding voltage | Insulation resistance | Dimension(mm) | ||||

| 1 | 20kV-2000pF |

≦0.0040 |

1.5Ur● 1min |

≧1.0×105MΩ |

D | H | L | D | M |

| 2 | 20kV-10000pF | 45 | 19 | 23 | 12 | 5 | |||

| 3 | 20kV-18000pF | 65 | 15 | 19 | 12 | 5 | |||

| 4 | 30kV-1000pF | 80 | 17 | 25 | 12 | 5 | |||

| 5 | 30kV-2700pF | 45 | 24 | 32 | 12 | 4 | |||

| 6 | 30kV-12000pF | 60 | 20 | 28 | 12 | 4 | |||

| 7 | 40kV-150pF | 20 | 33 | 41 | 8 | 4 | |||

| 8 | 40kV-500pF | 28 | 33 | 41 | 8 | 4 | |||

| 9 | 40kV-7500pF | 80 | 24 | 29 | 12 | 6 | |||

| 10 | 40kV-10000pF | 80 | 22 | 26 | 16 | 5 | |||

| 11 | 50kV-1000pF | 50 | 30 | 34 | 12 | 4 | |||

| 12 | 50kV-1000pF | 32 | 27 | 31 | 16 | 5 | |||

| 13 | 50kV-5600pF | 80 | 31 | 35 | 16 | 5 | |||

| 14 | 60kV-1500pF | 50 | 31 | 34 | 12 | 5 | |||

| 15 | 60kV-3000pF | 65 | 32 | 35 | 16 | 5 | |||

| 16 | 100kV-500pF | 50 | 54 | 58 | 12 | 5 | |||

| 17 | 100kV-2000pF | 51 | 32 | 35 | 16 | 5 | |||

| 18 | Insulator type 100kV-1500pF | 68 | 36 | 40 | 16 | 5 | |||

| 19 | 150kV-820pF | 65 | 95 | 100 | 12 | 5 | |||

| 20 | 200kV-600pF | 50 | 90 | 94 | 16 | 5 | |||

Core Functions:

The leap in performance at synchrotron radiation sources is largely due to innovations in beam injection technology. In particular, innovative schemes such as on-axis displacement injection, employed by fourth-generation sources, place extremely stringent demands on pulsed magnet power supplies: they must instantly deliver massive pulsed currents to generate precisely controlled magnetic fields, effectively driving the electron beam into or out of its intended trajectory. High-voltage doorknob capacitors are the core guarantee for the high-precision and high-stability operation of these high-performance pulsed magnet power supplies.

Challenge:

Why are pulsed magnet power supply requirements so stringent?

Take the fourth-generation High Energy Synchrotron Source (HEPS) as an example. The bumper magnet used in its booster extraction system requires the pulsed power supply to output a half-sine wave with a bottom width of less than 1 millisecond, with peak current fluctuations controlled within ±0.3% and waveform consistency deviations less than 5%. Any distortion or jitter in the current waveform can lead to:

Electron beam trajectory deviation, resulting in reduced injection efficiency and impacting the stability of the storage circulation intensity.

Synchrotron radiation beam position drift, affecting the directivity and data quality of the light at downstream experimental stations.

Solution:

Perfect combination of LC resonant pulse circuit and high-performance capacitors

This type of pulse power supply often uses an LC resonant circuit topology. A high-voltage doorknob capacitor (C) and the pulse magnet inductor (L) form a resonant circuit. Switching (e.g., IGBT) control generates the required high-quality half-sine current pulses.

In this application, the performance of the doorknob capacitor directly determines the quality of the pulse waveform:

Low-inductance design ensures a sharp pulse front: The capacitor's low equivalent series inductance and the overall circuit inductance together determine the pulse rise speed. Our low-ESL doorknob capacitors effectively ensure a sharp pulse front, meeting fast response requirements.

Highly stable capacitance ensures waveform consistency: Long-term capacitance stability and low drift are key to ensuring consistent pulse waveforms from time to time. We use highly stable ceramic dielectrics to ensure minimal capacitance variation even under frequent charge and discharge cycles (e.g., 50Hz operating frequency), thereby ensuring high repeatability of the injection process.

Efficient energy recovery: To reduce energy consumption and heat load, advanced designs incorporate energy recovery circuits. The capacitor feeds back the remaining energy through the recovery circuit during the pulse interval, which not only improves the efficiency but also reduces the interference with the output pulse waveform. This also requires the capacitor to have high efficiency and fast charging and discharging capabilities.