-

High Voltage Ceramic Capacitor

-

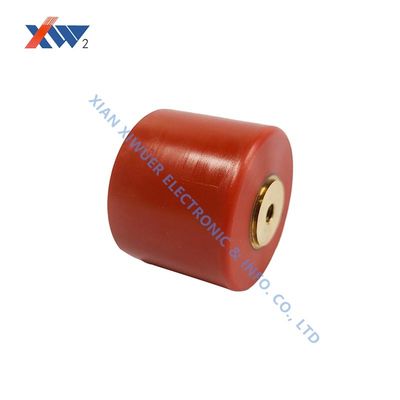

High Voltage Doorknob Capacitors

-

High Voltage Film Capacitor

-

Live Line Capacitors

-

Surge Protective Device

-

High Voltage Vacuum Circuit Breaker

-

Switchgear Temperature Sensor

-

Voltage Instrument Transformers

-

Capacitive Voltage Detector

-

Capacitive Voltage Divider

-

Capacitive Insulator

-

MOV Metal Oxide Varistor

-

PTC NTC Thermistor

-

High Voltage Resistors

-

Richard“XIWUER is very innovative. They have provided excellent, intuitive service, looking ahead into the future as to what we might need.”

Richard“XIWUER is very innovative. They have provided excellent, intuitive service, looking ahead into the future as to what we might need.” -

Mike"XIWUER's dedication to designing different specifications to meet our stringent processing requirements is a testament to our years of research and development."

Mike"XIWUER's dedication to designing different specifications to meet our stringent processing requirements is a testament to our years of research and development." -

Marry"XIWUER has impressive research capabilities and demonstrates good prototyping capabilities and high product quality."

Marry"XIWUER has impressive research capabilities and demonstrates good prototyping capabilities and high product quality."

High-voltage Doorknob Capacitors: A Promise Of Reliability In The Long-term Operation Of Synchrotron Radiation Sources

| Place of Origin | XIAN, CHINA |

|---|---|

| Brand Name | XIWUER |

| Certification | ISO9001,ISO14001,ISO45001 |

| Document | High Voltage Ceramic Capaci...25.pdf |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | Carton |

| Delivery Time | 5-7days |

| Payment Terms | L/C,T/T |

| Supply Ability | 4,000,000 pcs a year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Dissipation | ≦0.0040 | Withstanding Voltage | 1.5Ur● 1min |

|---|---|---|---|

| Insulation Resistance | ≧1.0×105MΩ | ||

| Highlight | high voltage doorknob capacitors,doorknob capacitors for synchrotron radiation,long-term reliable doorknob capacitors |

||

High-voltage doorknob capacitors:Long-term operation of synchrotron radiation sources

Drawing:![]()

Parameters:

| No. | Specification | Dissipation | Withstanding voltage | Insulation resistance | Dimension(mm) | ||||

| 1 | 20kV-2000pF |

≦0.0040 |

1.5Ur● 1min |

≧1.0×105MΩ |

D | H | L | D | M |

| 2 | 20kV-10000pF | 45 | 19 | 23 | 12 | 5 | |||

| 3 | 20kV-18000pF | 65 | 15 | 19 | 12 | 5 | |||

| 4 | 30kV-1000pF | 80 | 17 | 25 | 12 | 5 | |||

| 5 | 30kV-2700pF | 45 | 24 | 32 | 12 | 4 | |||

| 6 | 30kV-12000pF | 60 | 20 | 28 | 12 | 4 | |||

| 7 | 40kV-150pF | 20 | 33 | 41 | 8 | 4 | |||

| 8 | 40kV-500pF | 28 | 33 | 41 | 8 | 4 | |||

| 9 | 40kV-7500pF | 80 | 24 | 29 | 12 | 6 | |||

| 10 | 40kV-10000pF | 80 | 22 | 26 | 16 | 5 | |||

| 11 | 50kV-1000pF | 50 | 30 | 34 | 12 | 4 | |||

| 12 | 50kV-1000pF | 32 | 27 | 31 | 16 | 5 | |||

| 13 | 50kV-5600pF | 80 | 31 | 35 | 16 | 5 | |||

| 14 | 60kV-1500pF | 50 | 31 | 34 | 12 | 5 | |||

| 15 | 60kV-3000pF | 65 | 32 | 35 | 16 | 5 | |||

| 16 | 100kV-500pF | 50 | 54 | 58 | 12 | 5 | |||

| 17 | 100kV-2000pF | 51 | 32 | 35 | 16 | 5 | |||

| 18 | Insulator type 100kV-1500pF | 68 | 36 | 40 | 16 | 5 | |||

| 19 | 150kV-820pF | 65 | 95 | 100 | 12 | 5 | |||

| 20 | 200kV-600pF | 50 | 90 | 94 | 16 | 5 | |||

As a major national scientific and technological infrastructure supporting cutting-edge multidisciplinary research, the value of synchrotron radiation sources lies in their high uptime and sustained, stable photon output. An unplanned outage can disrupt dozens of experiments, resulting in immeasurable loss of scientific opportunities. High-voltage doorknob capacitors, core components of high-voltage power supplies and pulse systems, are crucial for their long-term reliability and lifespan, directly impacting the overall operational performance and scientific output of the facility.

Harsh operating conditions of capacitors in synchrotron radiation sources:

Continuous high-voltage stress: In the electron gun high-voltage power supply and the RF system DC link, capacitors operate at their rated high voltage for extended periods, placing a constant strain on the dielectric strength of the dielectric.

Frequent pulse shocks: In the pulsed magnet power supply, capacitors are required to charge and discharge with high currents dozens of times per second, withstanding severe current and thermal stress shocks.

Striving for extreme maintenance cycles: Synchrotron radiation sources typically have short annual maintenance schedules, which means that critical internal components must have a trouble-free operating time far exceeding this, avoiding field replacement during operation.

Our longevity gene: the ultimate pursuit of materials, craftsmanship and quality:

Aging-Resistant Ceramic Dielectric: Utilizing highly stable ceramic materials with rigorously optimized proportions and doping, this material effectively suppresses dielectric aging and ion migration under high electric field strength, ensuring highly stable capacitance over a decade.

Reinforced Electrodes and Connections: Advanced co-firing of metallized electrodes and ceramic dielectric creates a strong chemical bond, resisting thermal fatigue and electrical stress. Multiple reinforcement processes are employed for the screw terminals and internal electrodes to prevent loosening due to vibration.

Excellent Thermal Stability and Heat Dissipation: Low dissipation factor reduces self-heating at the source. Combined with the efficient heat dissipation of a metal housing or epoxy resin encapsulation, core temperature rise is kept low. A rule of thumb states that for every 10°C reduction in operating temperature, life doubles.

Strict Screening and Testing: We utilize accelerated life testing (e.g., 1000 hours at 85°C/rated voltage) and advanced reliability statistical models to ensure our products meet the most stringent reliability requirements, with predicted failure rates (FIT) below industry standards.